- SMT labelling machines

- Multi-station labelling machines

- High precision labelling machines

- PCB labelling machines

- Pallet labelling machines

- Automatic labelling machines

- High-speed labelling machines

- Double-sided labeling machine

- Self-adhesive labeling machine

- FPC adhesive backing machine

- Mobile phone adhesive backing machine

- speaker sticker backing machine

- Automatic backing machine

- Automatic adhesive backing machine

- Search

AFM-TZ1 Automatic plastic bracket roll material laminating machine

- Product:AFM-TZ1 Automatic plastic bracket roll material laminating machine

- Catalogue:Accessory labelling machines

- Views:177745times

- Update:2022/6/17 14:24:30

- Call:133-6065-4218

Automatic plastic bracket roll material laminating machine

Process description

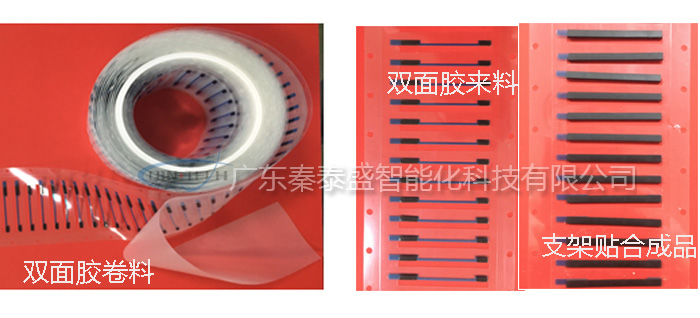

1. Double-sided rubber incoming material is coil material, assemble to the equipment feeding place, tear off the protective film

| Technical specification | |

| Machine size (length, width and height) | ≈1500*800*1500 |

| Service voltage of equipment (V) | AC 220v 50Hz |

| bleed pressure(Mpa) | >0.6 |

| weight(kg) | >150 |

| power(kw) | >2 |

| floor space(mm2) |

|

| precision | +/-0.1 |

| precision | ±0.1mm |

Equipment composition:

process description:

Manual will roll double-sided adhesive into the equipment, the equipment automatically feed; Vibration plate automatically output plastic support; The laminating module automatically absorbs the bracket and mounts with high precision (±0.1mm) and high speed (1.0-1.3s /PCS) under the coordination of two sets of vision systems; The collecting mechanism realizes automatic recovery of finished products after the completion of mounting. After a roll is completed, the device intelligently reminds personnel to replace the material.

Equipment requirements:

1. Less space occupied by automation, with customer standard equipment